Mechanical

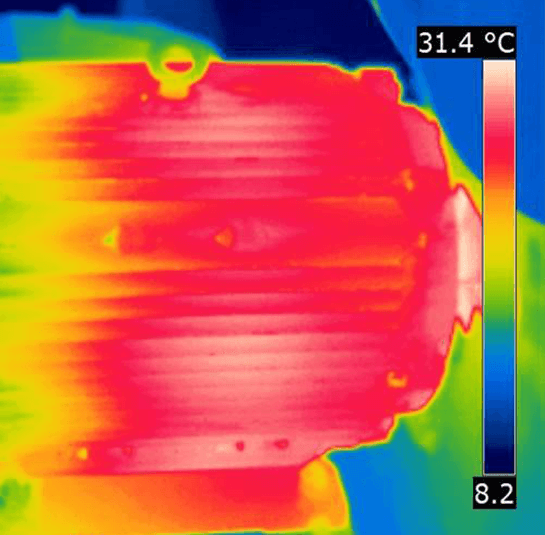

Our thermographic surveys allow operating conditions and mechanical fatigue to be analysed during production. Overheating, misalignment, liquid levels and temperature readings can all be made accurately and quickly with a thermal inspection. This is particularly useful for monitoring the condition of motors to ensure they are operating efficiently and safely.

The condition of pipe, tube and valve insulation can be easily analysed using thermal imaging. All types of leakage, blocked pipes and faulty insulation will clearly show up without having to check each pipe individually – saving you time and resources.

In addition, a thermography can be used to assess the feasibility of heat recovery from a process. We can then help you realise the potential for any energy savings.

Critical in mechanical thermography is that the survey does not interrupt production – the processes must be running to gain accurate readings.